Summit can fabricate PCBs ranging from simple 2-layer boards to highly complex designs with 30+ layers as standard, and emerging capabilities extend beyond 44 layers.

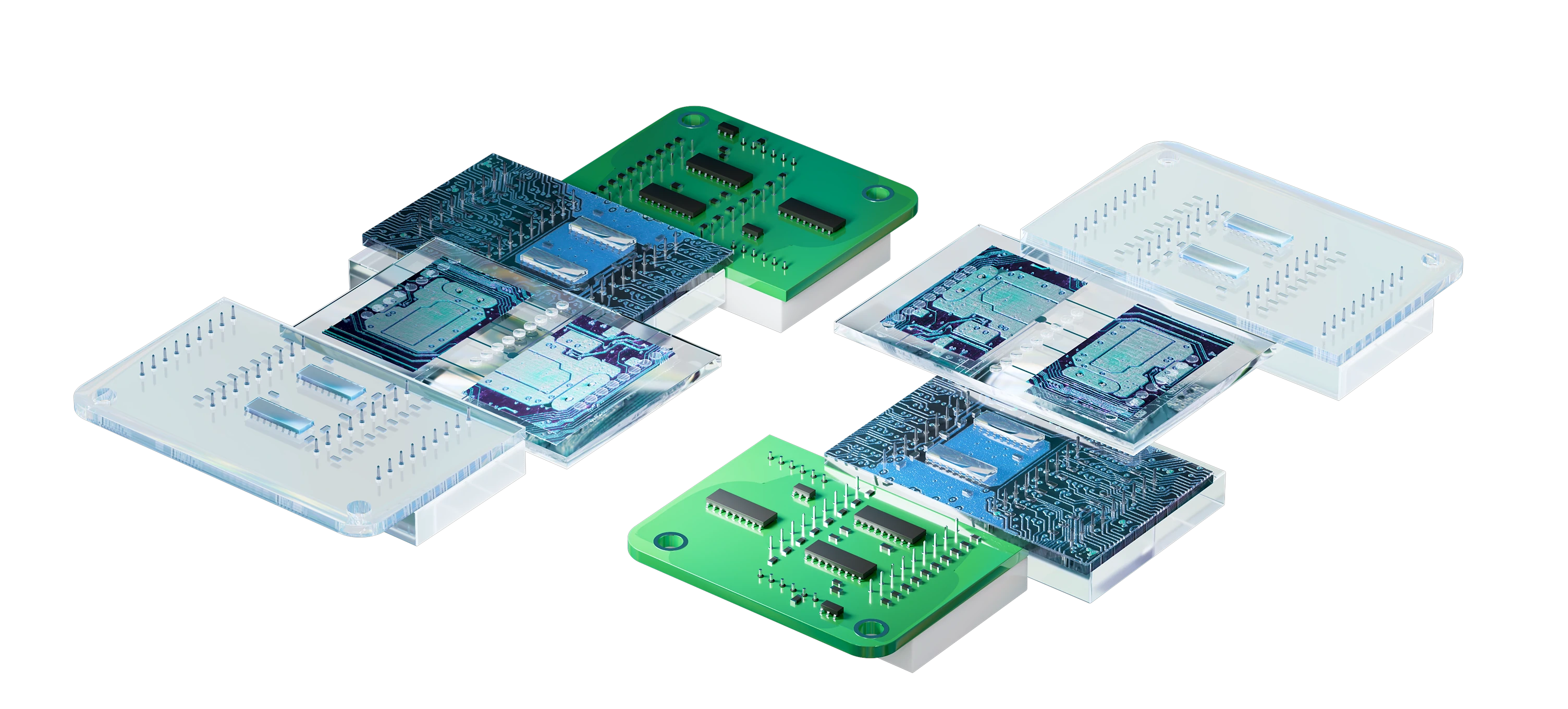

Manufacturing Capabilities Overview

Frequently Asked Questions:

-

-

Standard maximum panel size is 18″ x 24″, with advanced capabilities up to 21″ x 24″ and emerging capabilities reaching 24″ x 36″.

-

Yes, Summit offers HDI layers and sequential laminations from 2-3 up to 7 layers as permitted by laminate type.

-

Summit specializes in advanced PCB technologies including laser micro vias, blind vias, buried vias, and via-in-pad, with options for non-conductive, conductive epoxy, and copper-filled vias.

-

Summit offers HASL (leaded and lead-free), White Tin, ENEPIG, ENIG, Immersion Silver, and Entek Plus HT/OSP finishes for both standard and advanced applications.

-

Yes, Summit provides full turnkey PCB assembly including single and double-sided SMT, through-hole assembly, BGA placement, and additional services like box build, conformal coating, and functional testing.

-

Summit Interconnect maintains comprehensive quality certifications including AS9100D, IPC Class II and III, ITAR registration, and RoHS compliance. Certifications vary by facility based on specialized capabilities.

View our certifications by facility or contact us to match your project with the right certified location.

-

For inner layers with 1/2 oz. copper, Summit can achieve .003″/.003″ trace width/spacing in advanced capabilities, with emerging capabilities below .0025″/.002″.

Your connection to advanced PCB manufacturing

Your connection to advanced PCB manufacturing